|

© Copyright Materials All Rights Reserved SuperVoid 2011 |

|

Made In the U.S.A. |

Explanation of Design and Performance ExpectationsThe SuperVoid is created using an untreated mild carbon steel expanded sheet metal material. The sheet metal is process cut or slit and otherwise repetitively expanded, creating open diamond shapes, connected and bounded by remaining narrow strands, having an average open area of 75-80%. The primary design features of the 4” through 36” void series are the engineered placement of the corrugation and the waterproof nature of the materials comprising the SuperVoid.

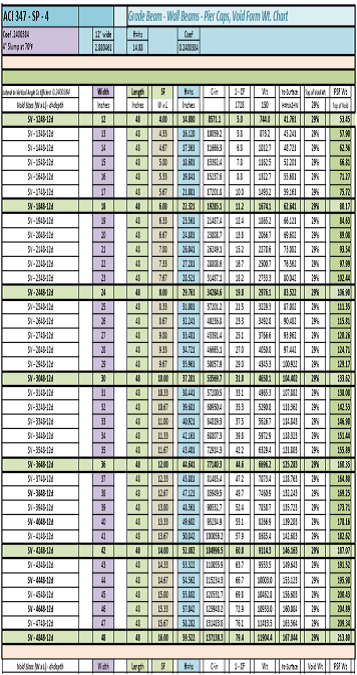

The processed material and completed unit profiles are arranged or positioned to provide maximum but limited opposing resistance. The opposing vertical portions of the materials are process bent, formed or fashioned as angular and positioned to array themselves and maintain relative equal diverging and converging angles of approximately 70° off of horizontal. We have developed load charts for the various requirements, which are based on repetitive performance testing both in house, third party and historical project experience records. Email your projects or call for specifics or particulars.

Some voids are assembled as SuperVoid units, using C-ring staples to fix the vertical and horizontal members together. These various material arrangements are assembled or otherwise unassembled for required sizes (void heights & widths) and designed for various load strengths. This allows for wide ranges of product applications, flexure and ductile reactions that will occur throughout the void form units and function as an overall system, providing “Structured Air” in Collapsible Envelopes.!!

Load reactions occur during the various loading scenarios that any void form product must endure. The portion of the void form that contacts the underlying soil works similar to a snow shoe. The open areas of the materials are otherwise bounded by narrow strands of steel material and provide predictable material structure.

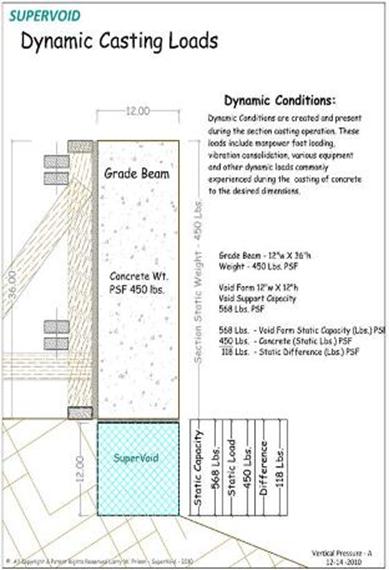

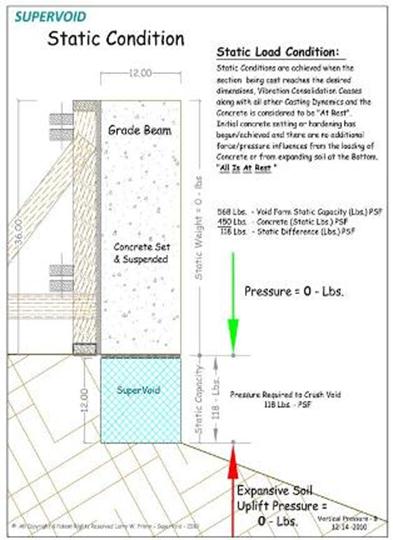

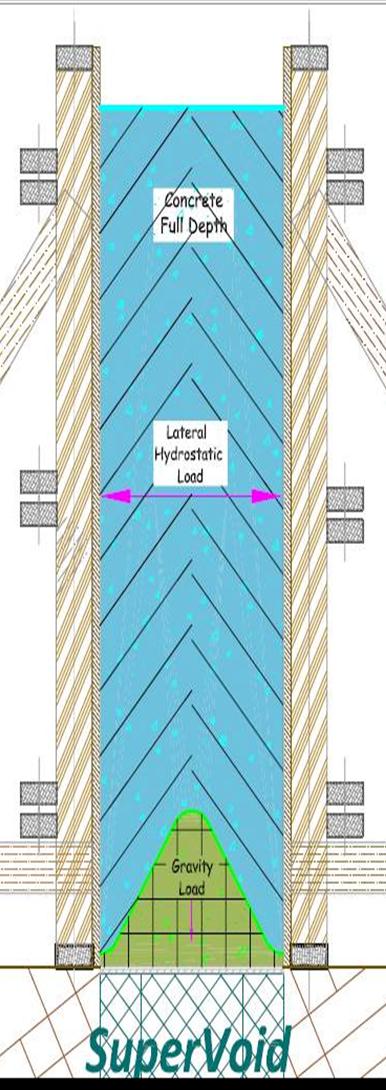

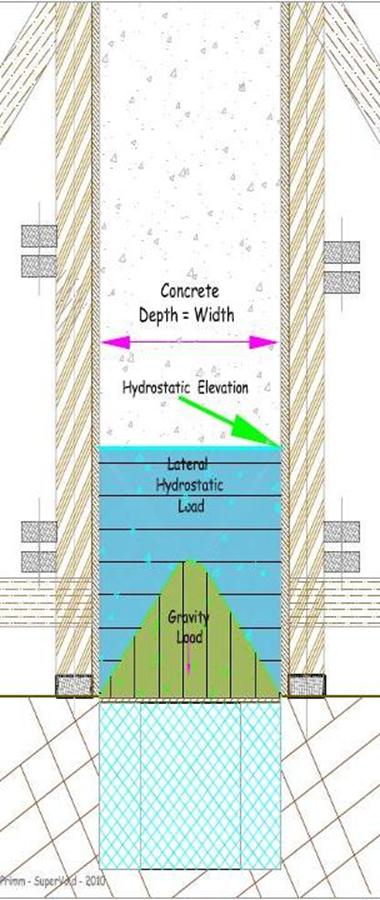

Casting - Accumulating weight/pressures resulting from increasing depths of concrete mass during the top loading of concrete against the coversheet substrates are transposed onto the horizontal top of the void substrate cover sheets and thus to the tops of the void forming units. These imposed loads defined as pressures, are redirected downward through the corresponding but offset vertical/horizontal profile portions of the void member in contact with the underlying soil. This continues (with respect to Grade Beams and or large 2’ to 8’ deep concrete Pier Caps) until the concrete is considered to be at or near hydrostatic conditions (subject to mix designs and the geometry of the section being cast). With the recommended ACI -347- SP-4, Guide to Formwork, procedures for the interval dipping use of mechanical vibration consolidation equipment, the wet plastic concrete materials can and do, quickly achieve the said hydrostatic results. The elevations at which the accumulating gravity loads transition from vertical to lateral, can be calculated and otherwise predicted with reasonable expectation.

At and near this hydrostatic elevation or condition, mass gravity weight and liquid head pressures exist, having been created by the plastic concrete. The addition in terms of depth of elevation, of more fresh plastic concrete material does not add further appreciable accumulated vertical gravity force/pressure to the top of the void products. Lateral Hydrostatic conditions are occurring or have been achieved. Above this point (Hydrostatic) the pressures are ensiled laterally against the opposing faces of its confinement (form faces of earth, wood forms & framing, steel, etc.) This information which is achieved through a series of calculations, helps to determine what dynamic and actual PSF load values (weight of fresh concrete as pressure in pounds per square foot) will be imposed on the void products or that can be expected to be supported by the void form. (References or Discussion Upon Request)

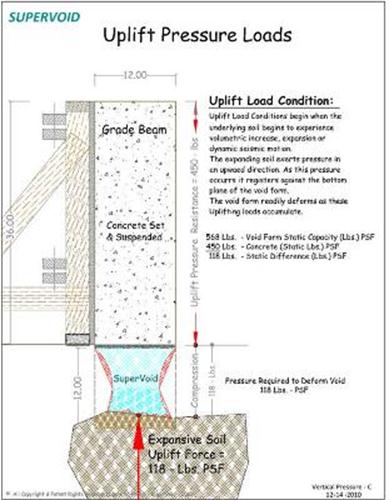

Resistance -In the process of the void form providing required and relevant load support, it must establish and maintain parity of resistance at the top and bottom of the void. Against the top it exerts a reflected load against the cover sheet. The cover sheet is used to create span, gather, collect, distribute or uniformly equalize top surface loads and the subsequent dynamic reactions during casting loads. At the same time the bottom of the void form must find resistance from the soil surface in order to offer load resistance. Time –When the section casting operation has been completed and the concrete is considered to be “at rest”. The concrete materials being thixotropic, begin the hardening/curing process when at rest. This curing timeline is not being addressed, but to state that additional increases and subsequent distribution of relative pressures created during the casting operation, also cease to increase as the “at rest” conditions are achieved. Maximum relative pressures against the SuperVoid have been obtained and endured. Time & Transition Away – As time occurs away from the “at rest” moment in time, the concrete begins to harden. The void form has satisfactorily performed its casting stage of work…, resisting imposed compressive loads. However, the SuperVoid form is now in a state of compression. This compression is the results of the plastic concrete mass and other appreciable accumulated loads being supported. These compressive loads being imposed upon the void form are also “at rest”, neither increasing nor decreasing, frozen in this instant of time. Compressive Load Transition – Moving forward beyond this time moment, one or more things can be expected to occur. The concrete will harden, and will remain fixed in its position as long as another force does not act against the cast section and overcome its inherent and increasing relative strength of resistance. The concept of a void form is used to provide and otherwise maintain an empty space of isolation and separation between the concrete structure and the underlying soils which may expand/contract. As mentioned the SuperVoid form is now enduring the resulting accumulated compressive pressure. As the concrete hardens and becomes firm, the initial increasing concrete mass gravity pressure influences on the void form unit erodes with the hardening to “net-zero”, increases. However…. the compressive pressures generated and endured during casting prior to “at rest” and subsequently hardened concrete, remains against the void form, which is now still in a state of resisting the imposed compression loads. The suspended concrete section has become a relative mass offering “0-gravity pressure” against the SuperVoid. The cast concrete section generally offers resistance factors which are at a minimum, equal to its sectional mass gravity weight (not counting or adding reinforcement, frictional coefficient or other resistant values). The Soil -So.. What happens now? Most commonly, in near time of days, weeks or months, the underlying soil will accelerate towards or away from the concrete which is separated by the void form. These movements will be caused by increased or decreased levels of moisture in the soil or may be caused by seismic activity. The soil will increase in volume with increased moisture and decrease in volume with decreased moisture. Often referred to as soil that Shrinks/Swells, Expands/Contracts, and Heaving, all the same. The most likely scenario occurring as a relative first, is that the soil moisture will equalize, then increase moderately, or rapidly with changing climatic conditions, with a resulting increase in soil volume and corresponding lateral and upward pressures.

Relief – The reactionary soil is the factor that completes the SuperVoid equation. If the soil dries out and contracts the void form has a corresponding reduction in existing or residual accumulated compressive pressure. This reduction can continue to “zero” or even below if the drying soil pulls or stretches the void form out of compression. The opposite, is the most likely, but not always. Prolonged or continuing drought conditions may result in little to no change.

The most likely will occur at an undetermined futuristic near point in time, when the soil will experience an increase in relative moisture content that produces volumetric expansion. If the event of expansion occurs as a relative first, the remaining resistant capacity of the void will be overcome by the resulting increased pressure. It will require additional pressure against the SuperVoid, at near to or equal that of the “balance... of SuperVoid original rated design values of resistance to compressive load pressures”. Summary-As stated above, the suspended hardened concrete section has become a relative mass which offers “0 - gravity pressure” against the SuperVoid. The concrete section also offers uplift resistance factors equal to its sectional mass gravity weight (not counting or adding reinforcement, frictional coefficient or other resistant values). As the expansive soils move upwards the residual and additional uplift pressures cause the SuperVoid to deform at very low pressures and do not allow the transfer of unwanted potential soil pressures to reach the isolated concrete structure being protected. “Structured Air” in Collapsible Envelopes.!!

References, Discussion & Additional Engineering Information - Upon Request © Copyright Materials All Rights Reserved SuperVoid 2011

|

|

SUPERVOID Engineering & Technical Information “Structured Air” in Collapsible Envelopes © Copyright Materials All Rights Reserved SuperVoid 2012

|

|

References, Discussion & Additional Engineering Information - Upon Request |

|

Click To Enlarge |